Speed, accuracy, and cost efficiency are some of the defining traits of modern industrial production. Repmold provides businesses with the ability to copy existing molds and components without needing to start the whole production process from the beginning. Focusing on mold reproduction and reverse engineering assists industries in cutting lead times, costs, and improving quality consistency.

This article discusses the industrial applications of Repmold methods, their benefits and challenges, and their potential future use, serving as an all-inclusive reference for engineers and other manufacturers.

What is Repmold?

Repmold defines the process of reproducing an existing mold or part. Repmold processes allow manufacturers to skip the time-intensive processes of designing new tooling and reproducing the molds from an original sample or component.

Repmold provides the greatest benefits in:

- Low to medium volume production

- Prototyping and rapid tooling

- Replacement of discontinued parts

Industrial Production Repmold Methods

Replicating Silicone Molds

Replicating silicone molds is one of the most common techniques in the use of Repmold.

How it functions:

- An original component is used to create a silicone mold.

- Then, liquid resins or elastomers are injected into the mold.

- Once the replicated component is cured, it is extracted.

Applications in Industry:

- Electrical parts

- Plastic housings

- Small mechanical components

Benefits:

- Rapid delivery

- Cost-effective tooling

- Fast turnaround and increased production

Resin Casting Repmold

Polyurethane and epoxy resins are used in resin casting to create components.

Applications are:

- Production of short runs

- Functional prototypes

- Visual and mechanical evaluations.

This technique is widely used in the manufacturing of consumer goods and automobiles due to its great surface finish.

Reverse Engineering Repmold

Precision is the main characteristic of the Repmold method of reverse engineering.

The process:

- Original parts are scanned through the CMM or 3D scanning.

- A CAD model is developed digitally.

- A new mold is generated through CNC or additive manufacturing.

Most suitable for:

- Old components or complex geometries

- Tight tolerance requirements

CNC-Based Repmold

Replicating molds using CAD/CAM systems is packaged with CNC engineering for a higher level of precision.

Advantages:

- Extended tool lifespan

- Sufficient for metal molds

- Outstanding precision

This technique is prevalent in the fields of industrial tooling, aerospace, and heavy machinery.

3D Printing-Assisted Repmold

The efficiency of the Repmold method is heightened with the use of additive manufacturing.

Benefits:

- Fast production of molds

- Validation of design

- Tooling inserts that save money

Silicone or resin molds are frequently used in conjunction with 3D printing to speed up production times.

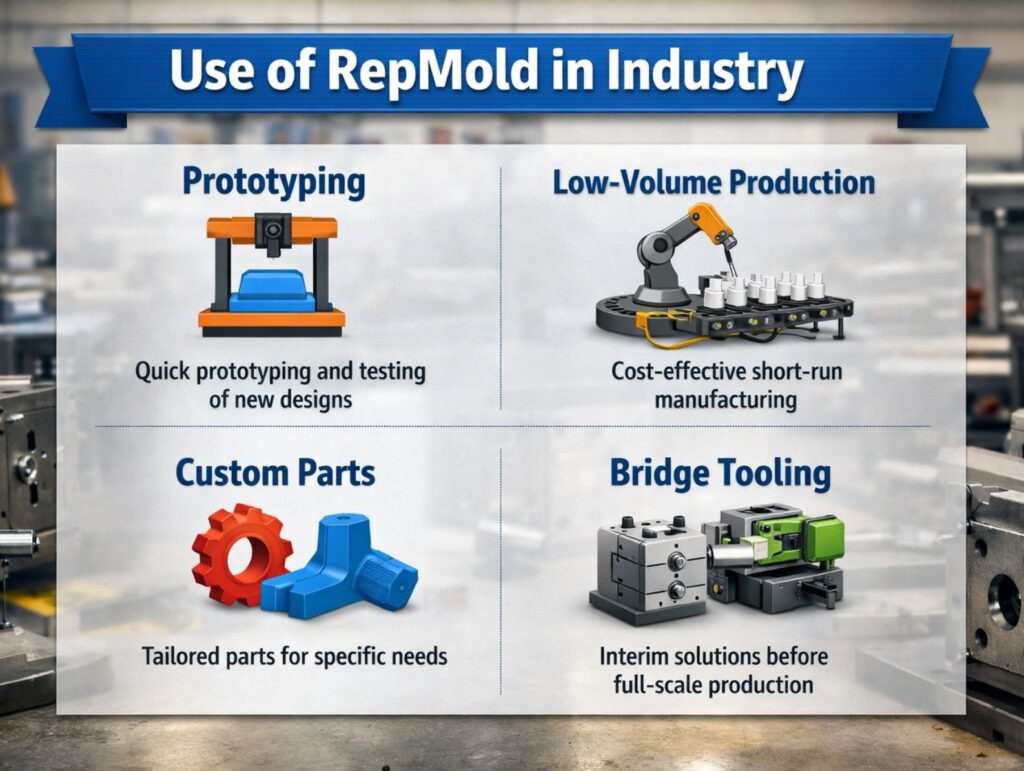

Use of Repmold in Industry:

Automotive Industry

- Replication of parts that are no longer available

- Custom tooling

- Components for interiors and exteriors

Aerospace Industry

- Components for maintenance and repair

- Tooling

- Parts that are precise and low in volume

Manufacturing and Machinery

- Jigs and fixtures used in industry

- Parts for the maintenance of equipment

- Gears and housings that are used as replacements

Consumer Goods

- Components of households

- Casing of Plastic

- Redesign and upgrade of products

Electronics Industry

- Parts for insulation

- Housings for connectors

- Enclosures that are tailored to specifications

Benefits of Repmold in the Industry

- Costs of development that are reduced

- Lead times for production that are shorter

- Repeatability, productivity, and quality are consistent

- Manufacturing in low volumes that is flexible

- Sustainable reuse of designs

These advantages make Repmold an important part of today’s manufacturing.

Challenges and Limitations of Repmold

Repmold has some drawbacks

- The condition of the part affects the accuracy

- The performance can be affected by the materials used

- Mass production of very high volumes is not ideal

- A high level of technical assessment is required

The condition of the part can limit the accuracy attained through Rep Molds, and the materials used can impact the performance of Rep Molds.

Comparison of RepMold versus Traditional Mold Manufacturing

| Aspect | RepMold | Traditional Mold Manufacturing |

|---|---|---|

| Cost to Start | Lower | Higher |

| Speed of Production | Faster | Slower |

| Best Production Quantity | Low to Medium | High |

| Design Flexibility | More Flexible | Less Flexible |

| Time to Market | Faster | Slower |

The Role of RepMold in Industrial Manufacturing

RepMold techniques are likely to become more accurate and scalable with the continued development of AI-powered design and adaptive 3D scanning, along with smart materials. With the convergence of RepMold techniques and the Fourth Industrial Revolution (Industry 4.0), its use in digital manufacturing systems will be even more beneficial to flexible manufacturing systems.

The envisioned use of RepMold techniques within industrial systems emphasizes the importance of manufacturing on-demand and the need for sustainable manufacturing processes.

Frequently Asked Questions

Which industries gain the most advantages with RepMold?

The RepMold process greatly benefits the automotive, aerospace, manufacturing, electronics, and consumer goods industries.

Is RepMold used for mass production?

RepMold processes are not designed to meet mass production requirements. Instead, they are intended for the low to medium volume production ranges.

How accurate is the RepMold process?

While the level of accuracy is determined by the process, the highest accuracy levels are attained using CNC and reverse engineering.

Final Thoughts

The RepMold techniques provide flexibility and adaptability to the industrial systems challenges they encounter. By creating the ability to replicate production molds quickly and cheaply, RepMold systems provide the ability to modify, reinforce, and maintain sustainable production methods.

RepMold will be an essential component to maintain the competitive, efficient, highly flexible production that the industrial systems will require.